Product

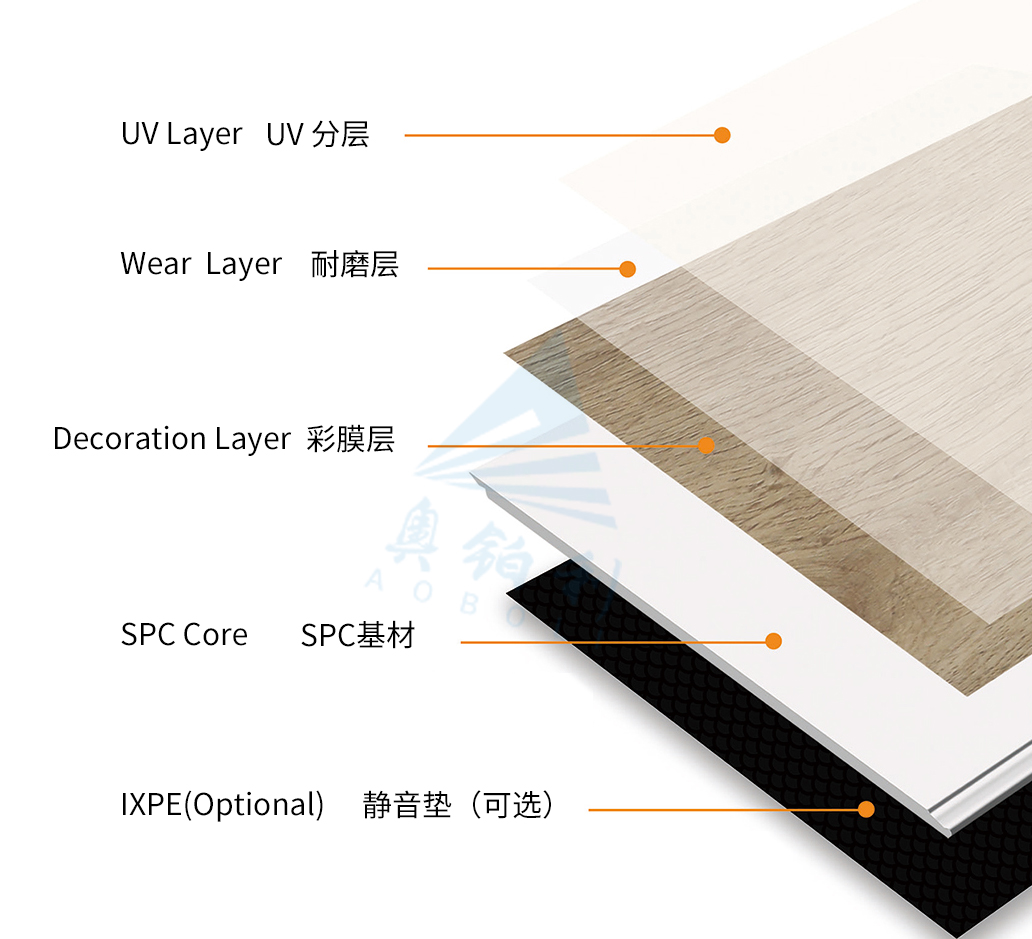

SPC stone plastic floor is made of pvc and calcium powder as the main materials. The PVC base material is extruded through an extruder, an internal mixing roller, and a calender. The PVC wear-resistant layer + PVC color film + PVC bottom layer are respectively pressed and pasted at one time. The product obtained by compounding and then slitting has a simple process. The lamination is completed by heat and does not contain glue. The difference between it and the traditional floor is that it does not contain harmful substances such as formaldehyde. It is a formaldehyde-free environmental protection board. Green and environmental protection, strong wear resistance, a wide variety of colors, waterproof and moisture-proof, fire-proof and flame-proof, sound insulation and noise-proof, fast installation and construction, heat conduction and heat preservation, convenient maintenance and so on.

Product Description

SPC calcium plastic floor description:

The English of SPC calcium plastic floor is: Multilevel composite board is also the abbreviation of rigid multi-layer composite PVC calcium plastic floor

SPC calcium plastic floor is a product made by extruding the PVC base material through an extruder, and using a four-roll calendering unit to separately press the PVC color film + PVC wear-resistant layer + PVC bottom film at one time. , Lamination is done by heat, no glue

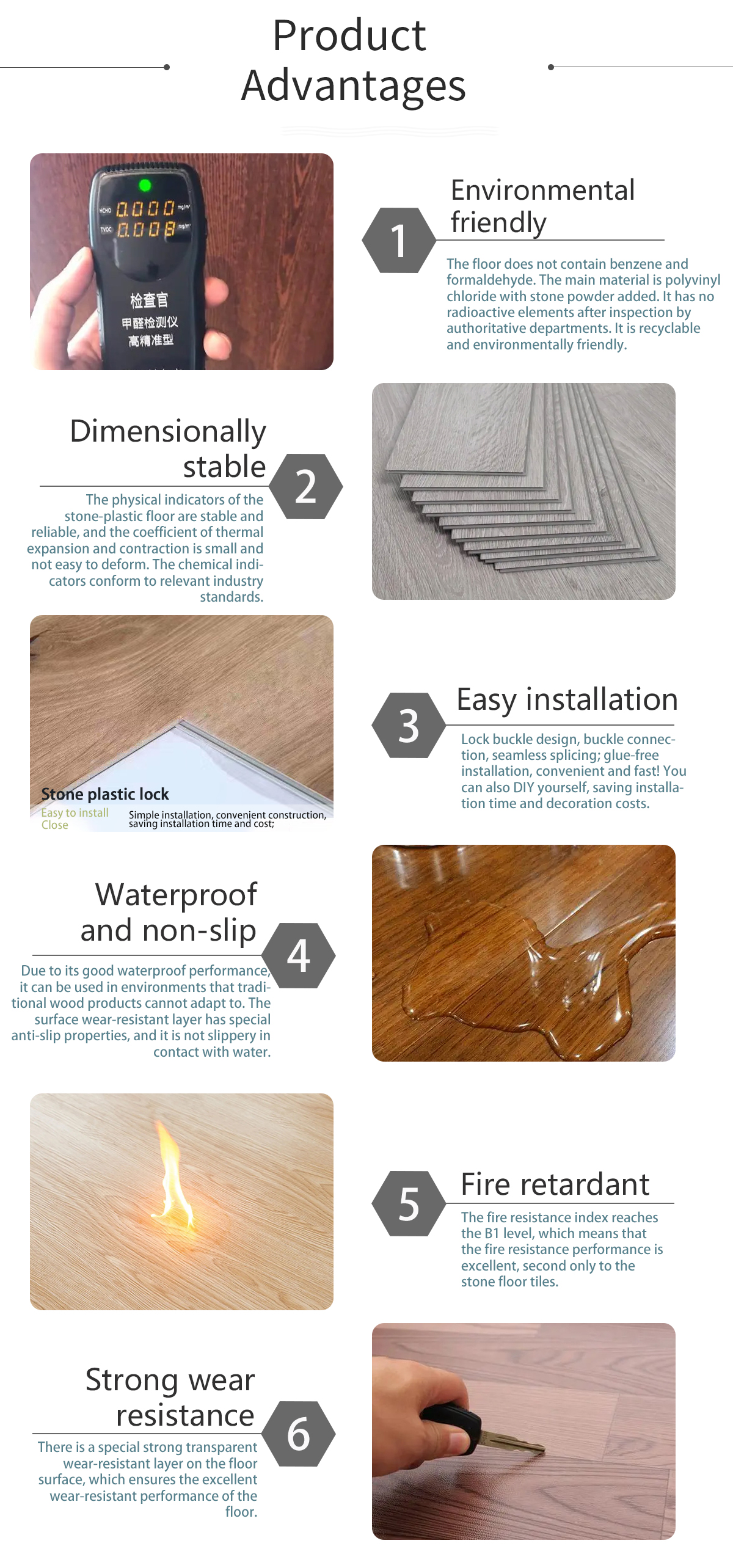

SPC calcium plastic floor material uses environmentally friendly formula, does not contain heavy metals, phthalate, formaldehyde and other harmful substances, in line with EN 14372, EN 649-2011, IEC 62321, GB 4085-83 standards.

SPC calcium plastic floor density: 1.9 ~ 2 tons / cubic meter;

Shrinkage rate of SPC calcium plastic floor: ≤1‰ (after tempering treatment); ≤2.5‰ (without tempering treatment). (Shrinkage rate test standard: 80℃, 6 hours standard)

Advantages of SPC calcium plastic floor: The physical index of SPC floor is stable and reliable, and the chemical index conforms to international and national standards!

SPC calcium plastic floor production process:

Step 1: Mixing

According to the proportion of materials, pour into → hot mixing with high-speed mixer → enter cold mixing and mix the materials uniformly through cooling;

Step 2: Extrusion

Add the conical twin-screw extruder for heating and extrusion → enter the sheet die for extrusion molding, the formed sheet passes through a four-roll calender, and the substrate is shaped → paste color film → paste wear-resistant layer → cooling → cutting , This series of processes is automatically completed on the production line.

Step 3: UV

Surface UV

Process 4: slitting and grooving + packaging

Slitting→grooving→inspection→packaging.

The advantages and development trend of SPC calcium plastic floor:

SPC calcium plastic floor has the advantages of fire prevention, waterproof, non-slip, environmental protection, durability and high cost performance. SPC flooring has been widely sought after in foreign markets because of its good quality performance and high cost performance, and has gradually formed a trend in China. In home decoration, the use of SPC flooring has become a trend, and it also reflects consumers' pursuit of health, environmental protection and quality life. It can be foreseen that in the near future, SPC plastic floor will gradually replace the existing common ground materials and occupy a place in tooling and home improvement projects.